From pine to shingle and everything in between…we bring you the photographic tale of our brand new roof!

These photos cover the span of time between December 23rd and May 3rd. During this time we completed work on other aspects of the lodge, but for this post we will focus on the roof construction.

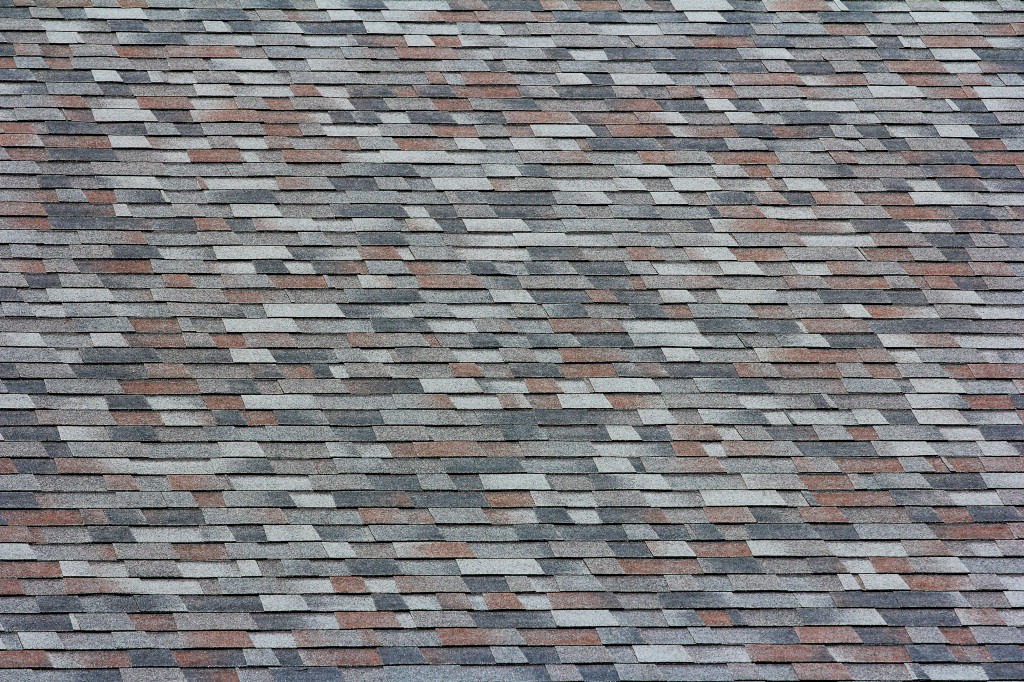

We went around and around with roofing options but we settled on a dark colored asphalt shingle. We think it looks great. What do you think?

Coteau des Prairies Lodge

We selected a heavy asphalt shingle which will hopefully weather well on the exposed peak of the Coteau des Prairies where gusty winds occasionally turn violent.

The roofers are no chickens. And they also can't fly. We were just hoping they wouldn't need that ability.

The roofing crew shingled the whole east side and most of the west side in one day! They were fast!

After the roofing underlayment was installed, we all felt a lot better knowing we wouldn't have to worry about water leaking through and warping or discoloring the pine underneath.

View of the entire length of the roof system. Picture taken from outside the north window.

Guests will be greeted with the view of this incredible great room ceiling and humungous north window when they first walk through the main entryway.

SIPs are installed! We begin seeing fewer signs of the great outdoors inside the lodge, such as snow for instance.

Nate Rude and Joe Breker confer in the future location of the observation tower in the middle of the roof. It's unanimous, the view is spectacular!

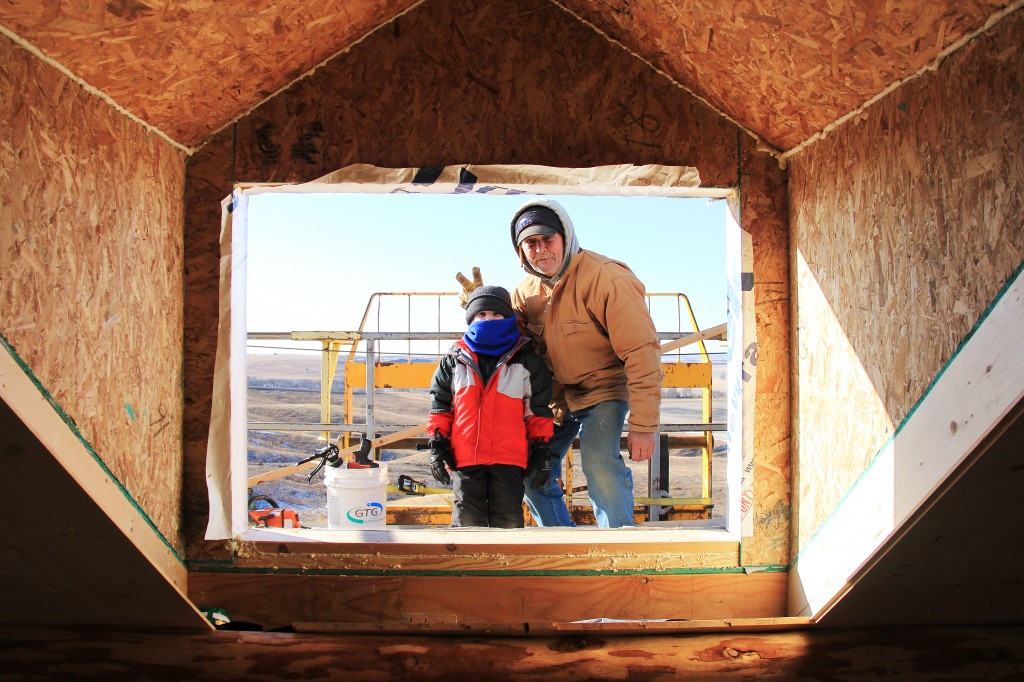

Gideon Breker helps Jerry Sapa build a dormer. Gideon likes to work with people who know how to have fun.

The crew lifts SIP panels into place and fastens them together to construct the dormers. Even the walls of the dormers are SIPs.

Benaiah Breker helps 'Papa' Joe fasten an attachment plate to a SIP. The ring in the plate attaches to a strap which is used to lift the SIP.

It is beginning to look like something now that the main SIPs are installed. Now the long awaited dormers are beginning to appear to give the roof some character.

Many pieces of high tensile hardware are used to fasten the gigantic SIPs to the purlins below.

Phillip Breker drives screws near seams to stengthen the SIP splines which are used to seal and fasten the SIPs to each other.

Justin Phillips screws long screws through the SIPs into the purlins which serve many important structural purposes. Not to mention aesthetic purposes!

The crew installing one of the last large SIP panels. What a great feeling to be all covered up!

We did get a little snow this winter. But thankfully we didn't get much because we wouldn't want to be doing this job in heavy snow!

Installing the last large SIP on the south end of the roof. The lodge remained like this for a couple weeks before the north window was ready to be covered.

The entryway header log is weathering the elements of a North Dakota winter, mild as it is. Soon, this log won't have to worry about such matters.

Notice the pine under the eaves of the roof? We stained these rough sawn pine boards using the same product we will use on the log wall.

Jerry Sapa and Justin Phillips work to prepare the north window and surrounding walls for roof installation.

For scale, Joe Breker stands next to a large stack of SIPs. Incredible but true, these styrofoam sandwiches provide amazing strength and insulation properties for a structure like ours.

The log wall inside the main entryway shivers under a frosty mantle of snow as it waits its turn to have a roof installed overhead.

Beautiful pine boards and purlins appear under the roof. What a treat it will be to stay in one of the loft rooms!

Even as winter's snow finally arrives, Coteau des Prairies Lodge sits patiently upon the hill as it waits for the rest of its roof to be completed.

Nate Rude rides the SIP like a giant surf board. Being a log builder, you know Nate doesn't do small.

Another enormous SIP sails overhead to its final resting place atop Coteau des Prairies Lodge!

Onlookers watch in amazement as Jeff Richards performs a sort of rare ceremonial contractor's dance to celebrate the placement of the 1st SIP.

The 1st SIP is hoisted into place by a large boom lift. We also used heavy straps attached to removable plates which were fastened to the SIP.

The structural and insulation properties of the roof will be provided by these Structural Insulated Panels (SIPs). The large panels measure 8'x30' and they are 10" thick.

Phillip Breker uses a large air stapler to attach 1" shiplap pine to the purlins. Remember to put the pretty side down!

Maria Breker takes a turn with the stapler. It is almost a shame to cover those pretty purlins, but at least we will see them from below.

Phillip and Joe Breker use the extra larger 'timber' saw to saw through eight 1" pine roof boards with one pass.

Nate Rude discovered a fun slide on top of the lodge. Yes, the basket was at the bottom to catch him.

Corey Arnold fastens pine boards to the purlins to give the underside of the roof a great looking finish.

looks good 2 me keep up the good work we all appreiciate what u r doing