In addition to ‘The Lookout’ featured in the previous post, August brought many other exciting new changes to the lodge. We have a few photos of the lookout floor installation process here along with a whole bunch of other gems mined from our photo collection. As you will see, we have been keeping pretty busy. And things are just getting busier as our opening date in October draws nearer.

Click on an image below to open the photo gallery.

This rich colored wood flooring is actually the same wood used for the log walls...Ponderosa Pine. We sanded it, stained it and coated it with multiple coats of floor grade varnish.

The finished floor in the south view lounge. We used this room as a test for our homemade flooring to see if we liked it enough to put it in the great room. We did.

This is the Breker family's first attempt at making homemade flooring. It's a good thing we were going for rustic. We actually quite like it. We intentionally left the circular saw kerfs from the milling process.

Olivia Stenvold, the lodge manager, has been busy, busy, busy doing everything from taking reservations to buffing and staining logs to cleaning the construction site to making big decisions. All while pregnant, she is expecting in January.

Doug Spieker will use any excuse to drive his Farmall H. So today his excuse is the lodge driveway need to be mowed. Thanks Doug!

Dan Thompson, our cabinet guy, also installed our vanity bases. They, along with our cabinets, doors and trim are knotty alder. We love how knotty alder has a rich color and all kinds of great character and knots.

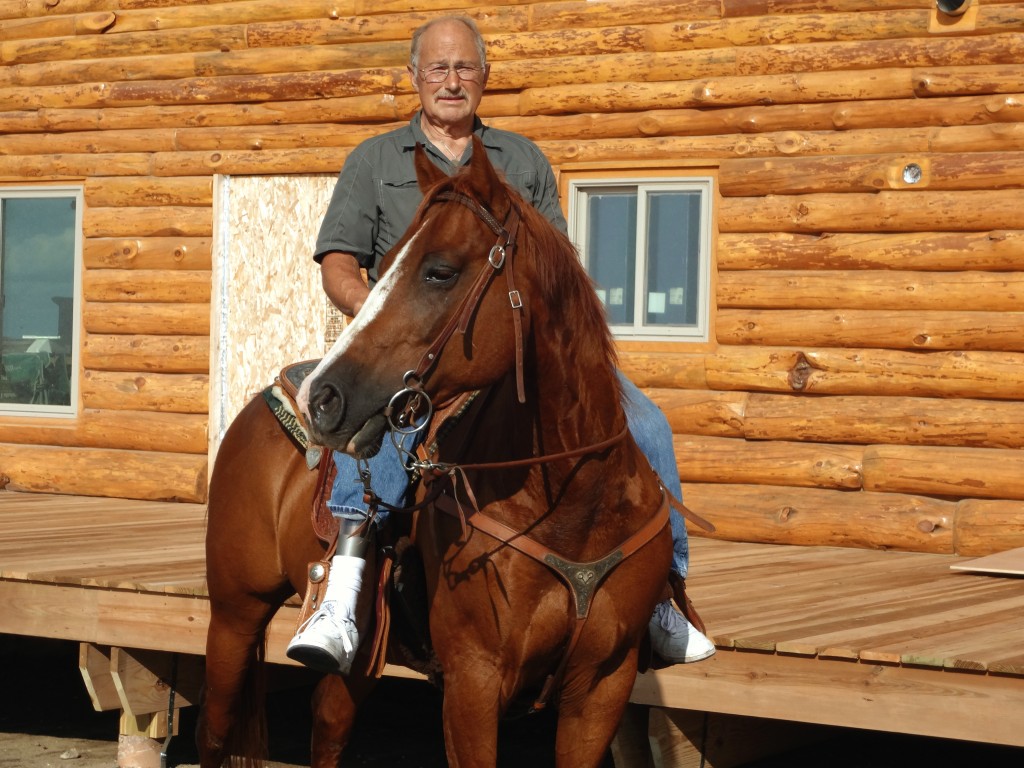

Phillip Breker and his son Benaiah go for a late afternoon horseback ride on PJ at Coteau des Prairies Lodge. The lodge will be a terrific place for trail riders to enjoy fun rides with fantastic scenery.

There is no one who can find deals on lodge and construction supplies better than Doug. And he has used his welding talent for creating everything from load bearing supports to railings to chandeliers to furniture to decor. Stud.

Patty Breker and Tracy Skar prepare a shower surround for tiling in the lower level suite. The suite includes a bedroom with large private bath, a private kitchen, living room and exclusive walk out patio on the pasture hillside.

Jay Callahan and Wilder Benites are on the log cleaning crew while Jennifer Hanson applies the first coat of stain. These long skinny logs will be the porch roof truss logs.

Jeff Richards and Jay Callahan work with Nate Rude to set a header log on the porch pillars. These structures line the east and west sides of the lodge and will be extra sturdy supports for the porch roofs.

Wilder Benites, Jeff Richards and Joe Breker work the porch pillar setting crew on a beautiful late summer afternoon. The porch roofs will be installed where the support 2x4s are attached.

Nate Rude uses a special kind of tar paper on the bottoms of the porch pillar logs to seal them from moisture and to prevent rotting. He does a nice job of cutting a pretty circle, don't you think?

Nate Rude determines the placement of the final porch pillar on the west deck. Actually this log will be a deck support pillar. There will be a smaller second floor deck off the south view lounge here.

Phillip Breker, our photographer, gets a shot of a newly installed granite and knotty alder bathroom vanity. This is typical of the 15 bathroom vanities in the lodge.

Paul Holland heads up the deck building crew. He and his crew built a very large pine deck which wraps around the west, south and east sides of the lodge.

The deck crew used a new fastener system on the deck which attaches the screws into the sides of the boards so the screw heads/holes are not visible. It looks really nice.

The decking crew begins to attach deck treads on the west side of the lodge. This will be the perfect place to come and enjoy a sunset with friends and family.

As you walk from the lodge entryway into the great room, you will see the office to your immediate left. This is where you will get your room key and get everything squared away with the manager on duty.

It's the cabinet discussion. Patty Breker makes her intentions known to Dan Thompson and Nate Rude for the main kitchen cabinets. It is going to be awesome!

Joe and Patty Breker meet with Dan Thompson, our cabinet maker, and Nate Rude, our general contractor, in the lower level kitchen to discuss cabinet details. The cabinets are knotty alder.

A photo collage of the 3 south bedrooms in the lower level. Patty Breker selected colors for the rooms as well as painted them. Each of the lodge's bedrooms will have a theme to go along with a corresponding color.

Phillip Breker enjoys a nice cigar while watching a beautiful sunset at Coteau des Prairies Lodge. It doesn't get any better than this. 🙂

The concrete crew preps a spot to pour a concrete pad for the lower level walk out patio. This walk out is basically right on the pasture hillside where guests will walk directly out of their room and into the pasture.

Another busy summer day at the lodge. A carpentry crew prepares the lookout roof for installation and a concrete crew digs a hole for deck footings.

A fresh, wet concrete pad cures in the summer heat. Notice the alternating directions of the texture. We thought, what the heck, let's try it. It wouldn't be the only unusual feature of the lodge.

Storbaken Concrete from Lidgerwood poured concrete pads, deck footings and a colored concrete patio outside the north lower level suite. This pad joins the deck near the main entryway.

Megan Goedert is one brave chick. Thirty feet above the great room floor, she give the truss logs their final buff before they will be finished with a clear polyurethane to enhance their natural beauty.

Olivia Stenvold and Megan Goedert tape the hardware on the great room roof trusses in preparation for Nate Rude to put on the final finish.

It seems like the log prep never ends. We will have selected, cleaned, installed, re-cleaned and finished over 1000 logs. This is the beginning of the pile for the porch roofs - pillars, headers and trusses.

Moo. Coteau des Prairies Lodge is located in the middle of the Breker cattle pasture. Fifty Black Angus cow/calf pairs graze the pasture in the summer months.

The pasture was nice and green in mid summer at the lodge. The pasture is perfect for morning hikes, it is fun to 'check the cows'. If you want to find them, just follow your ears...or your nose.

The lodge exterior hasn't changed appearance much this summer, except for the color of the logs, but that is about to change as you will see.

Dean, our taper, has the coolest tools. We thought Nate's tools were cool. Check out his sweet stilts, we are all wishing we had a pair of those things.

Our friend, Rodney Erickson, a local crop duster, sprays a maturing field of Joe Breker's corn a couple miles from the lodge. Pull up, Pull up!

The drywall hangers didn't have as much work to do on the main floor where the log walls provided the finished surface. Notice the sound board in the ceiling to reduce sound transfer between rooms.

Joe Breker uses a power planer to shape a piece of log siding during installation. To make a nice finished product, we used this method to match one piece to another.

Gideon Breker finds a fun perching spot in the loft. Its hard to resist monkeying around in the trusses, especially for Gideon.

Phillip Breker hoists a lookout floor truss log into place high above the great room floor. The blue fabric behind him is a tarp which covered the hole in the roof where the lookout would be built.

Nate Rude attaches the first log for the lookout floor structure. As you can see we used the boom lift. We had to tear a hole in the side of the lodge to use the lift for hoisting the large logs up into the roof trusses.

Nate Rude, the contortionist chainsaw operator, shaves a flat spot on a log roof truss to prepare installation of the lookout floor structure.

Nate Rude cuts special notches out of a log which will fit lookout floor truss logs. This is where Nate's unique craft really shines. It's like a giant piece of rustic furniture.